Home

>

Products > Laser Rangefinder Module > 1064nm Laser Target Designator > 100mJ 1064nm Laser Target Designator

100mJ 1064nm Laser Target Designator

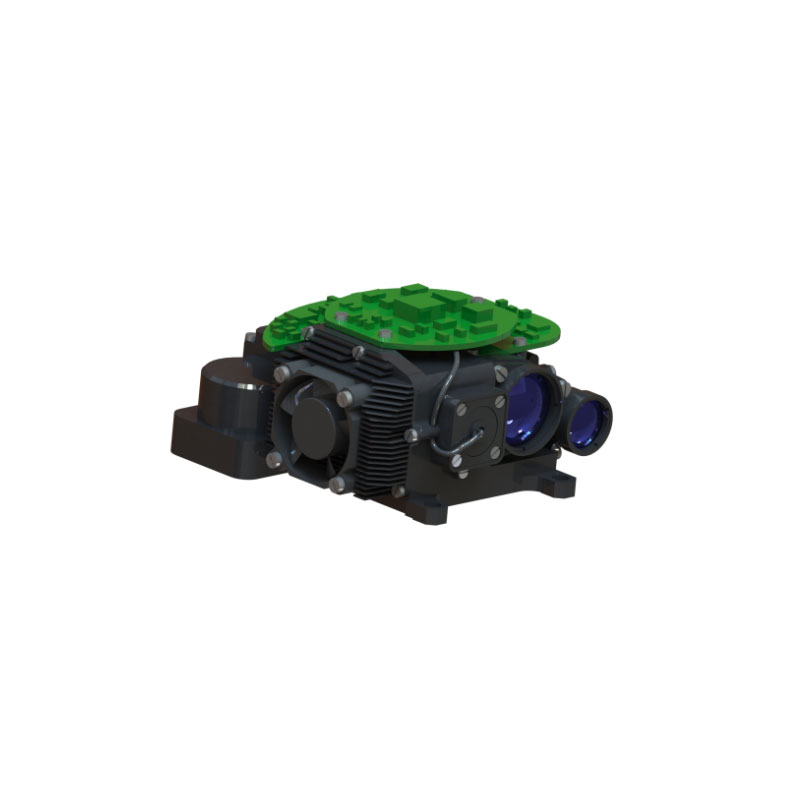

The STA-1064100M medium laser photometer (hereinafter referred to as the laser photometer) is a precision photoelectric product which transmits the laser to a specific target and calculates the distance information according to the laser flight time. 100mJ 1064nm Laser Target Designator has the characteristics of outstanding performance and simple operation.

Model:STA-1064100M

Send Inquiry

Product Description

Safety instructions

In order to use this product safely, please read this instruction carefully before operating this product

●This laser imager is a precision optical mechanical product. Failure to operate according to the regulations may result in dangerous laser injury. Do not open or adjust any part of the laser photometer, or attempt to repair or adjust the performance of the laser photometer.

●Pay attention to electrostatic protection: The electronic parts of the laser photometer are electrostatic discharge sensitive equipment. Do not touch any electronic equipment without protective measures.

●Turn on the laser photometer power for operation only within the specified voltage and power range.

●Do not touch the optical lens with your fingers or hard objects (to prevent grease contamination or scratches).

●Do not measure high reflectance targets at too close a distance (to prevent damage to detector core components).

●Do not store under non-specified conditions (high pollution environment, beyond storage temperature range, etc.).

●The laser photometer shall not be subjected to strong mechanical impact (vibration, impact, fall, etc.).

Do not expose the laser photometer to sudden temperature changes (> 3℃/min) (to prevent lens cracking).

●This laser imager is a precision optical mechanical product. Failure to operate according to the regulations may result in dangerous laser injury. Do not open or adjust any part of the laser photometer, or attempt to repair or adjust the performance of the laser photometer.

●Pay attention to electrostatic protection: The electronic parts of the laser photometer are electrostatic discharge sensitive equipment. Do not touch any electronic equipment without protective measures.

●Turn on the laser photometer power for operation only within the specified voltage and power range.

●Do not touch the optical lens with your fingers or hard objects (to prevent grease contamination or scratches).

●Do not measure high reflectance targets at too close a distance (to prevent damage to detector core components).

●Do not store under non-specified conditions (high pollution environment, beyond storage temperature range, etc.).

●The laser photometer shall not be subjected to strong mechanical impact (vibration, impact, fall, etc.).

Do not expose the laser photometer to sudden temperature changes (> 3℃/min) (to prevent lens cracking).

OVERVIEW

The STA-1064100M medium laser photometer (hereinafter referred to as the laser photometer) is a precision photoelectric product which transmits the laser to a specific target and calculates the distance information according to the laser flight time. It has the characteristics of outstanding performance and simple operation. The laser photometer belongs to the eye safety products, through the serial communication.

1.1.The main composition of laser photometer

Laser photometer is a precision photoelectric integrated product, and its main composition is shown in Figure 1:

1.1.The main composition of laser photometer

Laser photometer is a precision photoelectric integrated product, and its main composition is shown in Figure 1:

Laser photometer composition

1.2 The main functions of the laser photometer are as follows:

●Laser ranging function and real-time reporting distance value;

●Power polarity reverse connection protection, overcurrent and overvoltage circuit protection function;

●Can output laser light synchronization signal;

●Can report the current working temperature in real time, for the host computer to judge and calculate;

●Laser out times reporting function;

●Power on and power off control;

●With a single ranging, continuous ranging function;

●Laser ranging function and real-time reporting distance value;

●Power polarity reverse connection protection, overcurrent and overvoltage circuit protection function;

●Can output laser light synchronization signal;

●Can report the current working temperature in real time, for the host computer to judge and calculate;

●Laser out times reporting function;

●Power on and power off control;

●With a single ranging, continuous ranging function;

100mJ 1064nm Laser Target Designator TECHNICAL SPECIFICATIONS

| Wavelength | 1.064μm |

| Output energy | total temperature: 100mJ ~ 120mJ, average output energy ≥110mJ, single pulse energy > 100mJ (2 seconds before removal) |

| Adjacent pulse energy fluctuation range | ≤8% |

| Beam dispersion Angle | 0.15mrad (the acceptance method adopts hole-hole method, and the ratio of hole-hole to hole-free is not less than 86.5%) |

| Spatial pointing instability of beam | ≤0.03mrad (1σ) |

| Irradiation frequency | accurate coding 45ms~56ms (check code 20Hz) |

| Pulse cycle accuracy | ≤±2.5μs |

| Pulse width | 15ns±5ns |

| Irradiation time | no less than 90s, interval 60s, or no less than 60s, interval 30s, 4 cycles of continuous irradiation at room temperature and low temperature, 2 cycles of continuous irradiation at high temperature |

| Ranging range | the minimum value is not more than 300m, the maximum is not less than 35km (23km visibility, medium atmospheric turbulence, for 2.3m×2.3m target, target reflection coefficient is greater than 0.2) |

| Irradiation distance | for 2.3m×2.3m target, not less than 16km |

| Normal temperature power-up preparation time | <30 seconds |

| Low temperature power-up preparation time | <3 minutes |

| Service life | ≥2 million times |

| Ranging counting range | 200m ~ 40km |

| Ranging accuracy | ±2m |

| Accurate measurement rate | ≥98% |

| Ranging frequency | 1Hz, 5Hz, 10Hz, 20Hz |

| Installation datum and laser transmission optical axis of non-parallel | ≤0.5mrad |

| Installation datum flatness | 0.01mm (design guarantee) |

| Insulation resistance | under standard atmospheric pressure, the insulation resistance value of the specified measuring point should conform to the provisions of Table 1 |

Table 1 specifies the insulation resistance values of the measuring points

| Serial number | Environmental conditions | Insulation resistance | Megohm meter output voltage |

| 1 | Standard atmospheric conditions | 20 m Ω or greater | 100V |

◆External logo (including product number) should be fixed firmly, clear, complete and easy to identify.

PRINCIPLE OF RANGING

After the laser imager is started, the laser pulse with a periodic frequency of 1Hz is emitted, which reaches the measured target through the transmitting antenna. Most of the beam is absorbed or diffusely reflected by the target, while a very small part of the beam returns to the receiving antenna and converges on the detector module. The detector module samples the reflected signal and obtains the distance information of the measured target through an algorithm.

Examples of calculation:

Measurement time (one round trip) =10us

Propagation time (one way) =10us/2=5us

Ranging distance = Light speed × travel time =300000km/s×5us=1500m

Examples of calculation:

Measurement time (one round trip) =10us

Propagation time (one way) =10us/2=5us

Ranging distance = Light speed × travel time =300000km/s×5us=1500m

RANGING CAPABILITY IN DIFFERENT VISIBITY

Atmospheric visibility has a great impact on the ranging performance of laser photometer. Please refer to Figure 2 for the ranging capability of this product in different visibility.

Figure 2 The relationship between the ranging ability of laser photometer and atmospheric visibility

HUMAN EYE SAFETY

The laser rangefinder uses a laser source in the band of 1064nm. When using the laser in this band, it is necessary to avoid the outgoing beam directly into the human eye as far as possible to prevent human eye injury.

MECHICAL INTERFACE

The mechanical interface of the laser photometer consists of 3 through holes, which are fixed to the installation platform by 3 M5 screws. The dimensions of the mechanical and optical interfaces are shown in Figure 3 below.

Figure 3 shows the mechanical and optical interfaces

COMMUNICATION PROTOCOL

7.1 Electrical interface of laser photometer

| Serial number | Name | Instructions | Notes |

| From 1 to 5 | +28V |

|

|

| 12-16 | +28V_GND |

|

|

| 6 | T+ | Laser send | RS422 communication |

| 7 | T- | ||

| 8 | R- | Laser reception | |

| 9 | R+ | ||

| 10 | GND | communicatively | |

| 17 | SYNC_IN+ | Laser reception | Synchronization signal input |

| 18 | SYNC_IN- | ||

| 19 | SYNC_OUT- | Laser output | Synchronization signal output |

| 20 | SYNC_OUT+ | ||

| 11 | Control signal _+12V | Power-on control | Signal current usage ≤20mA |

| 21 | Control signal _GND |

7.2 Software

7.2.1 Communication protocol definition

422 bus is used for data exchange between the laser imager and the upper computer, and its characteristics are as follows:

7.2.1.1 Baud rate: 38.40kbps;

7.2.1.2 Byte construction: low byte first, high byte after; Low byte first, high byte last;

7.2.1.3 Byte composition format: 1 starting bit, 8 data bit, 1 stop bit;

7.2.1.4 Communication cycle: 20ms.

7.2.2 The system software sends instructions to the laser photometer

The work instructions sent by the system software to the laser photometer are shown in Table 2.

7.2.1 Communication protocol definition

422 bus is used for data exchange between the laser imager and the upper computer, and its characteristics are as follows:

7.2.1.1 Baud rate: 38.40kbps;

7.2.1.2 Byte construction: low byte first, high byte after; Low byte first, high byte last;

7.2.1.3 Byte composition format: 1 starting bit, 8 data bit, 1 stop bit;

7.2.1.4 Communication cycle: 20ms.

7.2.2 The system software sends instructions to the laser photometer

The work instructions sent by the system software to the laser photometer are shown in Table 2.

Table 2: Work instructions

| Instructions | Meaning |

| 55 02 AA | Single ranging |

| 55 03 AA | 1HZ Ranging |

| 55 04 AA | 5HZ Ranging |

| 55 0A AA | 10HZ Ranging |

| 55 0B AA | 20HZ Ranging |

| 55 00 AA | Stop ranging |

| 55 0C 0D AA | Query instructions |

7.2.3 The laser photometer sends data to the system software

Table 3: Query the feedback data information

| Serial number | name | Instructions | Notes |

| 0 | Frame header | 0xAA |

|

| 1 | Flag bit | 0x0A |

|

| 2 | Route A current |

|

|

| 3 | Route A current |

|

|

| 4 | Flag bit | 0x0B |

|

| 5 | B current |

|

|

| 6 | B-way current |

|

|

| 7 | Flag bit | 0x0C |

|

| 8 | C path current |

|

|

| 9 | C path current |

|

|

| 10 | Pulse width |

|

|

| 11 | Pulse width |

|

|

| 12 | standby |

|

|

| 13 | Spare |

|

|

| 14 | Spare |

|

|

| 15 | Status word |

|

0x0A: Route A is enabled 0x0B: Route B is enabled 0x0C: Route C is enabled 0x0D: Route ABC is enabled |

| 16 | Temperature |

|

|

| 17 | Frame tail | 0x55 |

|

Table 4: Range echo data information

| Serial number | Name | Instructions | Notes |

| 0 | Frame header | 0xAA |

|

| 1 | Distance value high byte |

|

|

| 2 | Distance value low byte |

|

|

| 3 | Status word |

|

|

| 4 | Laser self-check status |

|

|

| 5 | Spare |

|

|

| 6 | Spare |

|

|

| 7 | Frame tail | 0x55 |

|

7.2.4 Accessories

In addition to the laser photometer, this product includes the following accessories:

◆Product packaging box (for batch products)

◆Operation and maintenance manual

◆Product certificate

◆Product history

◆Muslin gloves

◆J30J-21TJL connectors

In addition to the laser photometer, this product includes the following accessories:

◆Product packaging box (for batch products)

◆Operation and maintenance manual

◆Product certificate

◆Product history

◆Muslin gloves

◆J30J-21TJL connectors

MAINTENANCE AND SERVICE

8.1 Cleaning, maintenance and storage

Cleaning of the laser photometer includes cleaning of the lens and cleaning of the housing.

Lens cleaning:

8.1.1 Dust particles should be blown away using an air blow ball. 8.1.2 Fingerprints should be first dipped in a small amount of alcohol ether mixture with cotton wipe, and then in the shade of natural air dry.

8.1.3 Do not use cloth to clean the lens.

Cleaning of the case:

8.1.4 The structural parts should be lightly rubbed with alcohol and let dry naturally.

8.1.5 Keep electronics, plugs, and cables as free of moisture and dirt as possible.

8.2 Maintenance of laser photometer:

There is no need to maintain the laser photometer under normal working condition. It needs to be maintained after being stored in a dust-free environment for more than one year. The maintenance methods are as follows:

8.2.1 Check whether the laser photometer is normal in appearance.

8.2.2 Check that all screws are secure.

Storage of laser photometer:

8.2.3 Dry the product thoroughly before packaging.

8.2.4 Shall not be stored in the open air in the field, suitable for storage in the temperature of 0℃ ~ 35℃, relative humidity is not greater than 80%, no corrosive substances erosion, no strong mechanical vibration and impact, no strong magnetic field conditions.

8.3 test

Operators should properly connect and send correct instructions in strict accordance with power and communication definitions.

8.4 After-sales service

Laser photometer for precision products, when there is a fault, the need to return to the factory for fault analysis, positioning and maintenance, is not allowed to repair.

Cleaning of the laser photometer includes cleaning of the lens and cleaning of the housing.

Lens cleaning:

8.1.1 Dust particles should be blown away using an air blow ball. 8.1.2 Fingerprints should be first dipped in a small amount of alcohol ether mixture with cotton wipe, and then in the shade of natural air dry.

8.1.3 Do not use cloth to clean the lens.

Cleaning of the case:

8.1.4 The structural parts should be lightly rubbed with alcohol and let dry naturally.

8.1.5 Keep electronics, plugs, and cables as free of moisture and dirt as possible.

8.2 Maintenance of laser photometer:

There is no need to maintain the laser photometer under normal working condition. It needs to be maintained after being stored in a dust-free environment for more than one year. The maintenance methods are as follows:

8.2.1 Check whether the laser photometer is normal in appearance.

8.2.2 Check that all screws are secure.

Storage of laser photometer:

8.2.3 Dry the product thoroughly before packaging.

8.2.4 Shall not be stored in the open air in the field, suitable for storage in the temperature of 0℃ ~ 35℃, relative humidity is not greater than 80%, no corrosive substances erosion, no strong mechanical vibration and impact, no strong magnetic field conditions.

8.3 test

Operators should properly connect and send correct instructions in strict accordance with power and communication definitions.

8.4 After-sales service

Laser photometer for precision products, when there is a fault, the need to return to the factory for fault analysis, positioning and maintenance, is not allowed to repair.

Hot Tags: 100mJ 1064nm Laser Target Designator, Manufacturers, Suppliers, Factory, China, Made in China, Customized, High Quality

Related Category

905nm Laser Range Finder Module

1535nm Laser Range Finder Module

1570nm Laser Range Finder Module

1.54um Laser Rangefinder Module

1064nm Laser Target Designator

Anti drone ststem module

Ranging Lidar Module

Send Inquiry

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.